The Serviplast Engineering Department, to get your project off to a good start

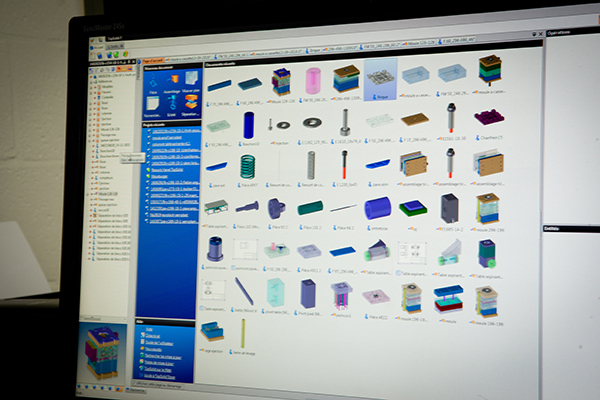

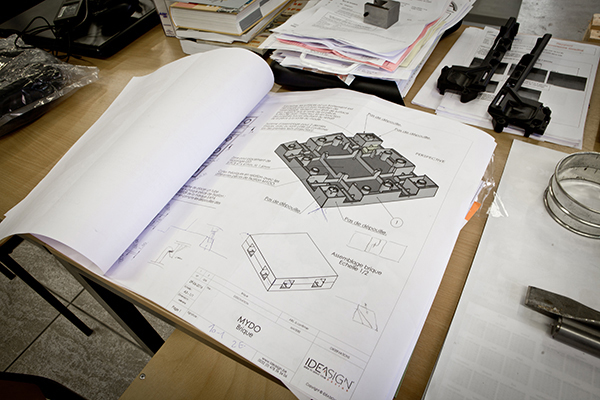

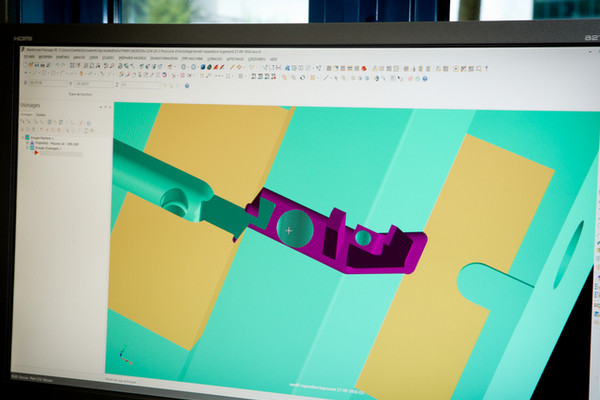

The Serviplast Engineering Department works with you from initial concept to the final plan for your part. CAD software, injection simulation and 3D prototyping enable you to design a part which fully meets your specifications.