Our plastic injection projects

MyDo

This project was conceived by the Serviplast Engineering Department and included tooling, parts injection, functional assembly of the components, packaging and logistics.

ADB

Phase 1: Preparation of cables for overmoulding by our assembly team:

- Cable and wire cutting

- Removal of sheaths and/or stripping

- Insert crimping

Phase 2 : Santoprene cable overmoulding by the injection unit

Tableup

TableUp is the first product in the Izzylife line developed by Serviplast. This is a system to raise tables to facilitate access by people using a wheelchair. Serviplast took care of the tooling, parts injection, functional assembly of the parts, packaging and logistics.

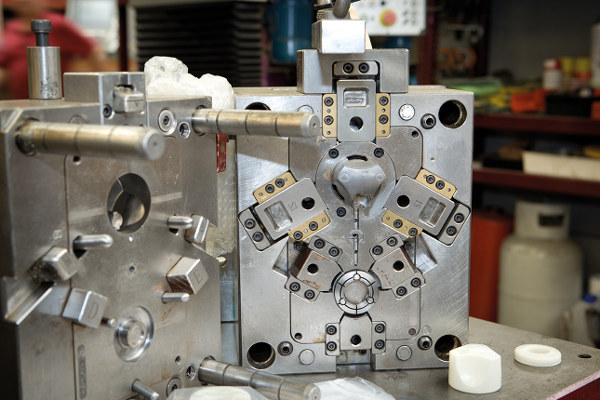

Amphenol

For this project, we did PEEK collar injection, which requires high-temperatures, and special tool maintenance.