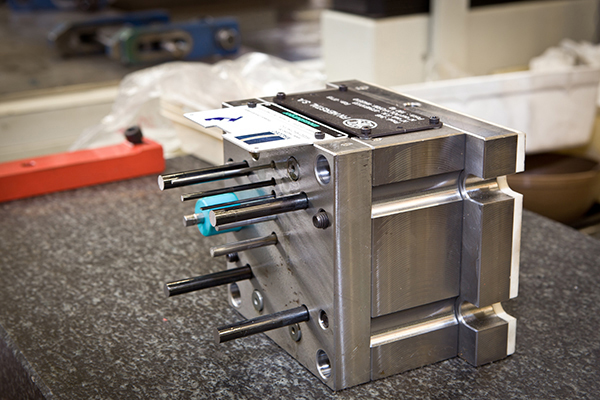

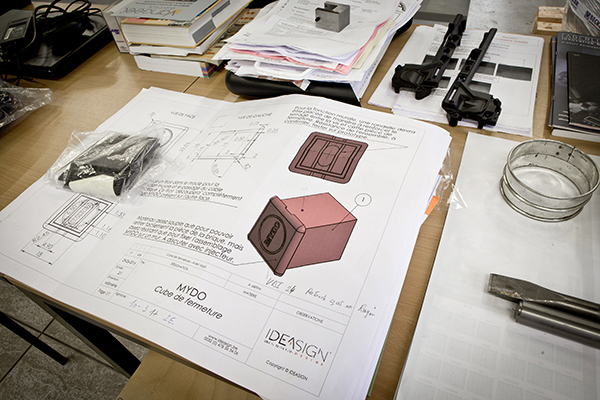

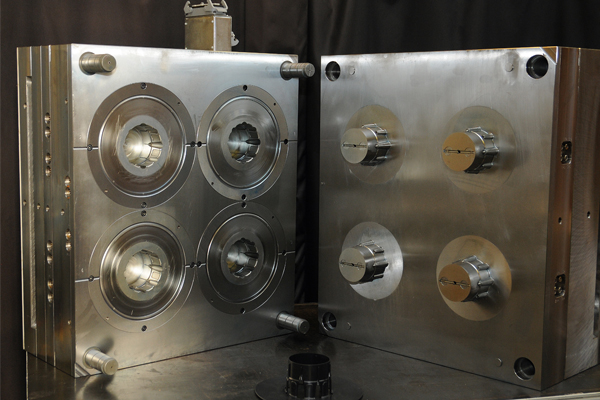

Serviplast Outillage, quality mould design and manufacturing

Secure your plastic part production with high-quality moulds. Serviplast Outillage brings you over 40 years of experience in tooling, from design to manufacturing. Mould design and manufacturing quality is essential to ensure high-performance technical and lower cost production.