24 Apr Serviplast, plastic injection moulding expertise

From designing to shipping your product, Serviplast, a social enterprise, uses its expertise to complete your project.

Specializing in plastic injection moulding for over 30 years, Serviplast Industrie has developed an additional range of integrated services to support you, from designing to shipping your part around the world.

An additional range of integrated services

Design office

From the idea to the final plan, the Serviplast design office guides you through your part’s design. 2D and 3D drawings, 3D prototyping and injection moulding simulation help you define the product that best meets your specifications.

With its tooling and injection moulding expertise, Serviplast enables you to optimize your part’s production from the design phase.

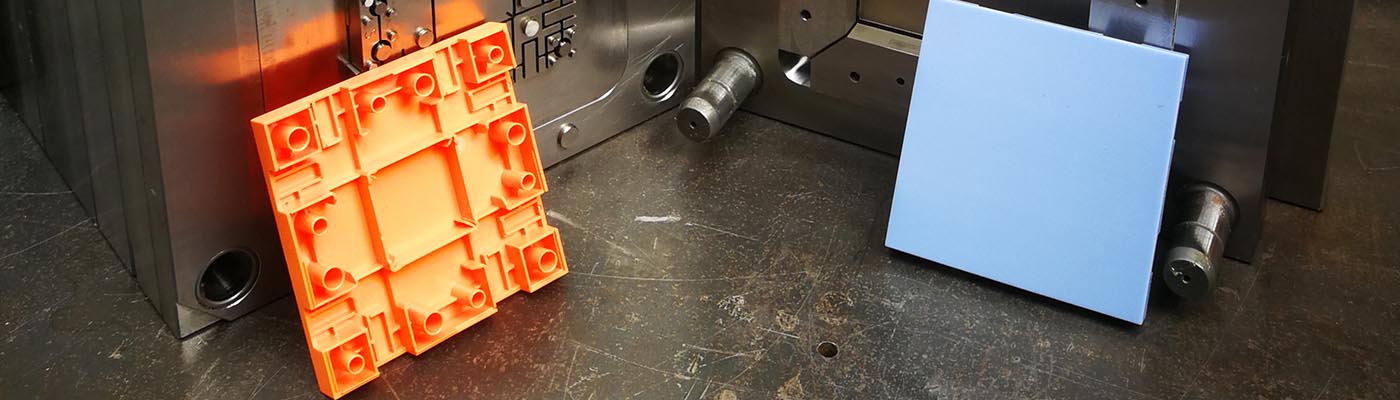

Tooling

With our precision machining workshop, Serviplast designs and manufactures your plastic injection moulding tools. We oversee the process and can make all necessary changes. We also produce precision parts for laboratories and research centres.

Injection moulding

Serviplast offers its clients comprehensive injection moulding expertise on a huge range of plastic materials, for all application types (PP, PE, ABS, POM, PA, PEEK, TPE, TPU, PVC, PC/ABS, etc.). Our clients come from varied sectors, including the aerospace, automotive, rail, equipment manufacturing and design industries.

Serviplast has 25 injection presses from 22 to 300 tonnes, which are regularly updated. ISO 9001 and ISO 14001 certified, Serviplast delivers its ongoing ambition to meet clients’ requirements and protect the environment.

Assembly and packaging

Connectivity, electrical equipment configuration, assembly and packaging complete the range of services. The overmoulding of injection-moulded metal inserts is first prepared by the Assembly Department.

Logistics

The secure storage and shipment of your products around the world make Serviplast a reliable partner to your supply chain.