30 Oct Robotization and automation serving the productivity and the well-being

Keeping a high level of productivity and increasing the well-being of the workers, these are the two dimensions of the new project that Serviplast just launched for its customer, Tarkett. Two dimensions which reply to the dual identify of the company : economical and social.

The priority of the competitiveness

For many years, Serviplast has integrated the robotization to its production of plastic pieces. As part of a new project for its customer Tarkett, an additionnal stage has been crossed with the automation of the palletization.

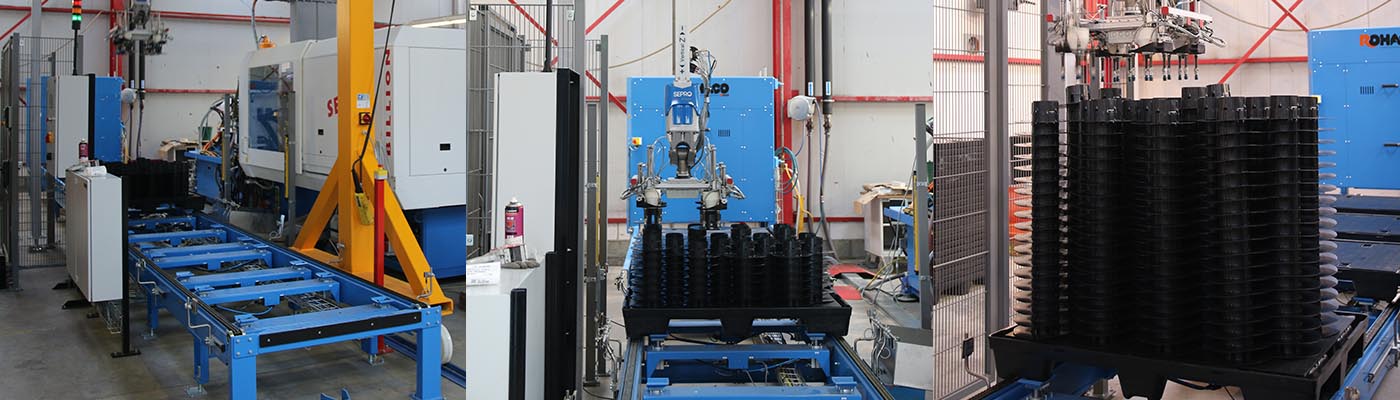

In partnership with the press manufacturer Billion, Serviplast worked with the company Sepro to create the setting up of a robot and an automated palletization line. In total, 4 different programs have been developped for each diameter of the pieces. The difficulty was the palettization of 22 successive layers with a repositioning during each placing without exceeding the scheduled cycle times. In order to reach this goal, we had to develop a specific gripping arm while optimizing the movements of the robot.

With an annual production of 700,000 pieces at the beginning to get to 1,200,00 pieces yearly, the robotization and automation are essentials conditions to meet the requirements of our customers.

A value-added work thanks to the robotization

The social mission of Serviplast is to create jobs for people with disability. Is the robotization of the production not against this objective ?

The robotization is the opportunity to change the work of the operators in order to give it added value. Instead of a repetitive work of handling the pieces coming out of the machines, the worker has the total responsability of the production : supply of the substance, the weighing and the packaging. It also makes him more aware of his responsibilities regarding the quality control of the pieces.

The automation of the palettization in this project for Tarkett allows also to limit the carrying and so to reduce the accident and disease risks.

The robotization and the automation are totally in harmony with our social aim. They add value to operators’ tasks and increase the well-being of the workers.