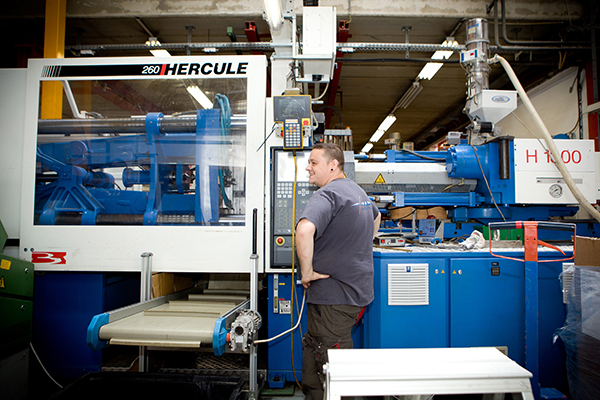

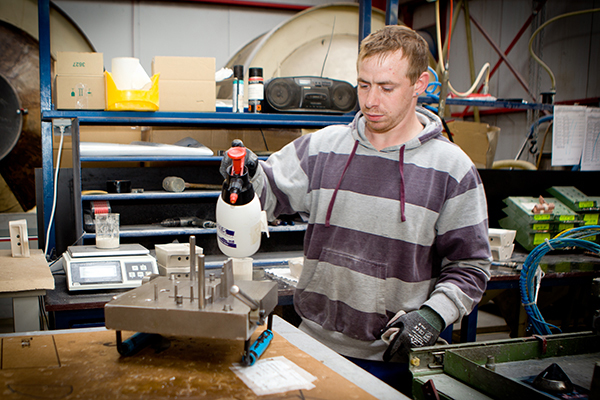

Serviplast, your plastic injection specialist

Thanks to its expertise in quality and on-time production processes, Serviplast provides you with high-performance solutions for your plastic injection parts. Serviplast specialises in small and medium series production runs and in overmoulding and insert placing and provides you with its technical expertise and flexibility.